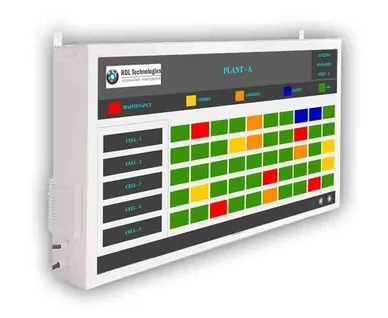

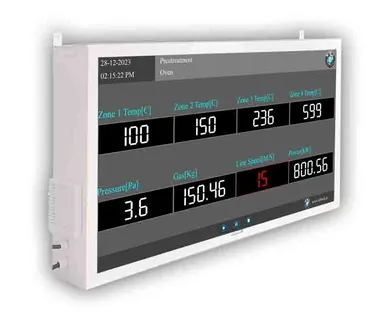

Human Machine Interface - HMI

Human Machine Interface (HMI) is a device that enables line operators, managers and supervisors to monitor and control the machinery and manufacturing process in order to improve product quality and efficiency. HMI supports .net, QT and Web based applications for easy IoT Application Integration.