RDL MES 4.0

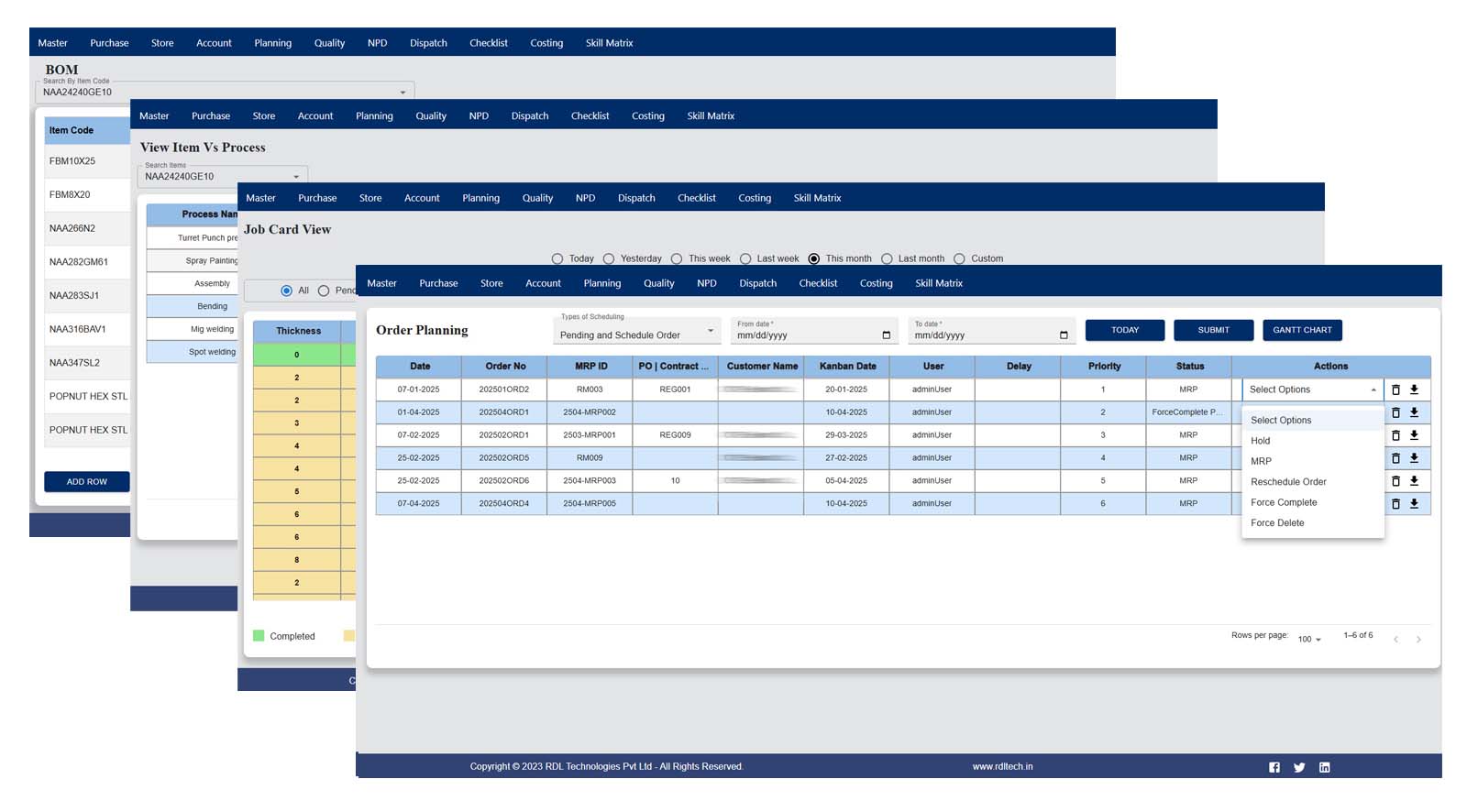

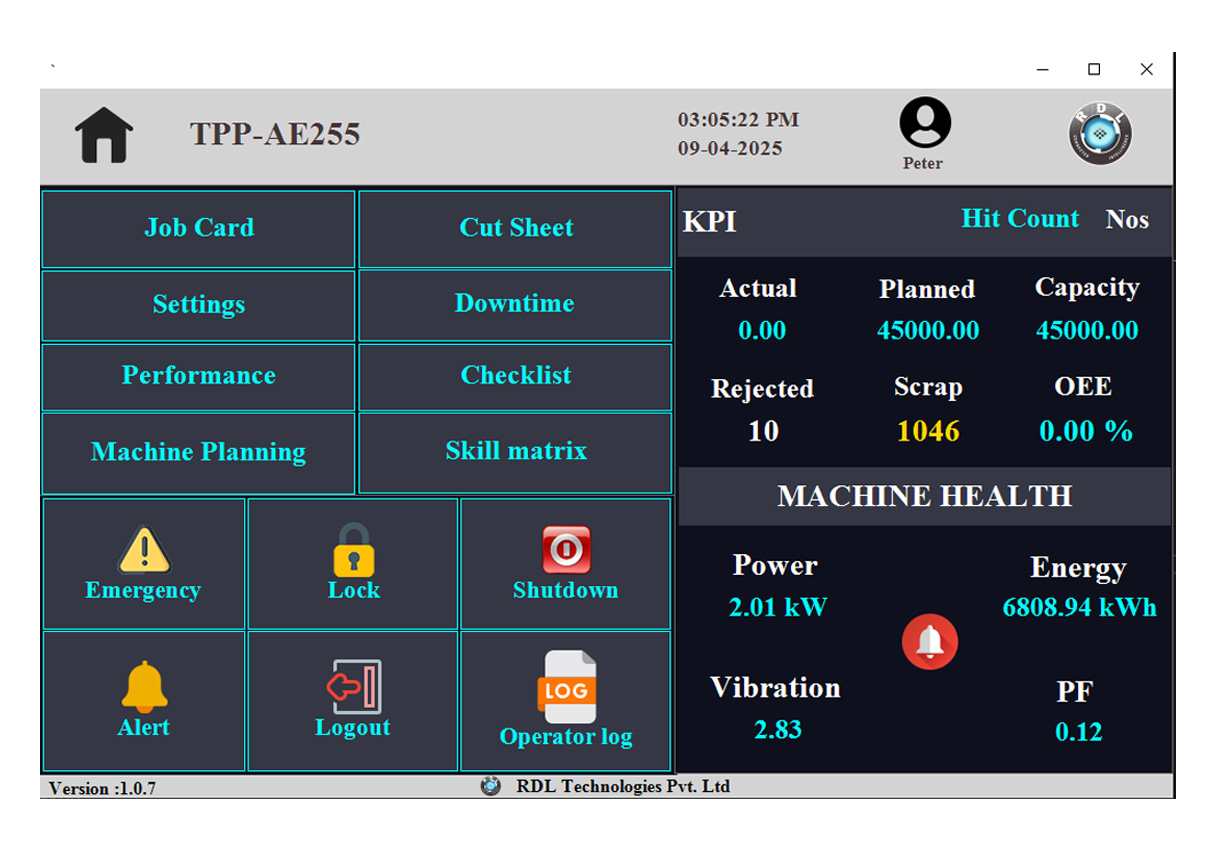

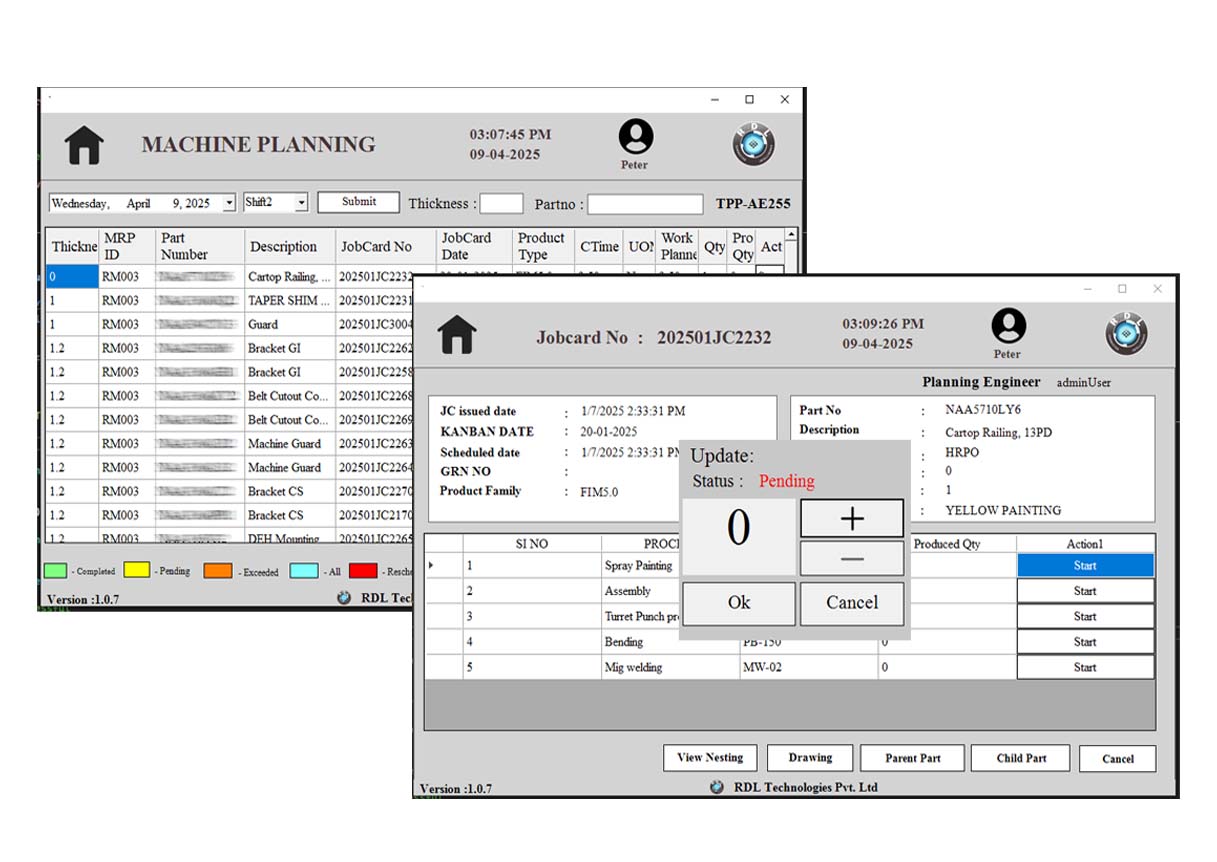

Every manufacturing unit's success depends on effective planning and scheduling based on a variety of shop floor dynamics (machine availability, operator availability, raw material, production lead time, breakdown and vendor process, etc.). It also involves identifying the specific losses that lead to low machine productivity, as well as procurement, sales, and finance, as well as closely monitoring market trends.

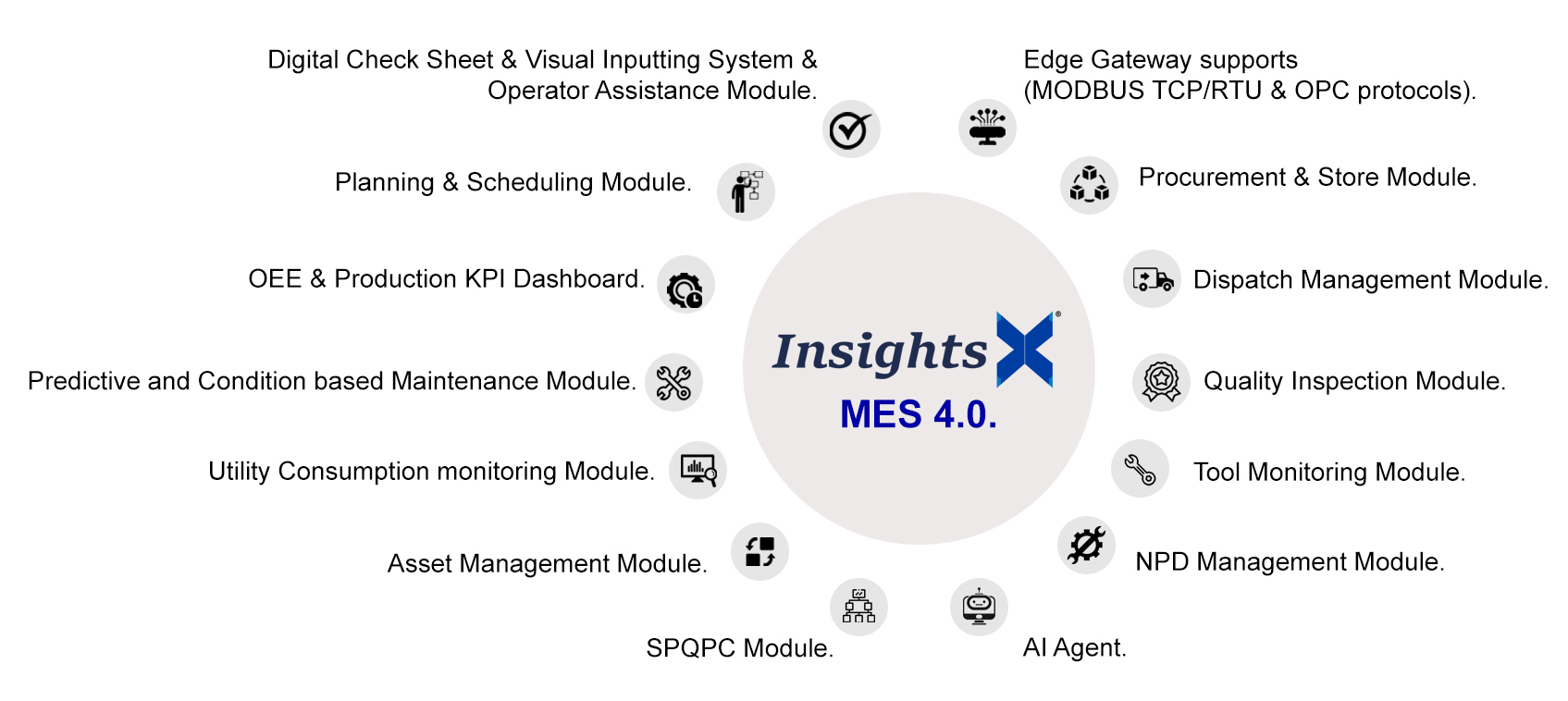

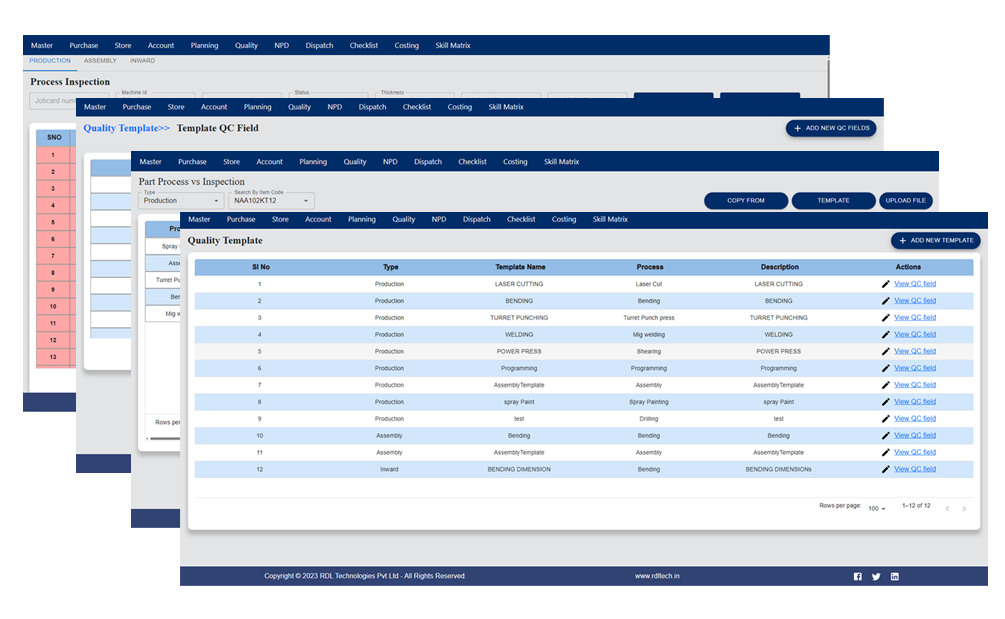

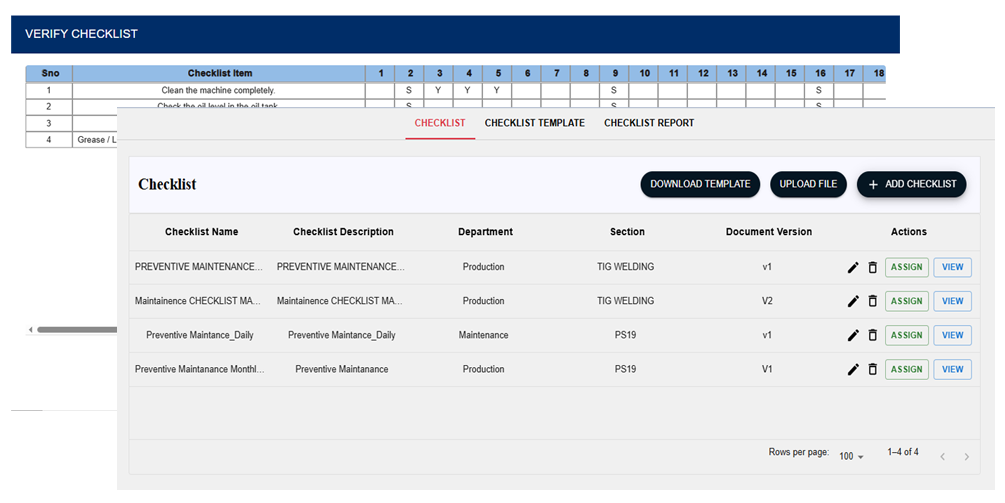

The RDL MES 4.0 Manufacturing solution integrates IT and OT to drive end-to-end digital transformation across the enterprise through the integration of industrial AI and IoT. Our cloud-/on-premise-based solution helps digitize day-to-Day manufacturing processes , improving operational efficiencies, asset performance, productivity, utility consumption and wide-scale sustainable value creation.